Winglets: The Tiny Part of Wings

Have you ever observed out of the airplane window and speculated what those tiny vertical pieces are at the end of the wings? Those are called winglets.

In the world of aviation, efficiency is pivotal. One of the significant breakthroughs that have significantly boosted the performance of modern aircraft is the invention of winglets. Aircraft winglets, those vertical or near-vertical extensions at the wingtips of modern planes, are a prevalent sight in today’s aviation industry. They play a critical role in enhancing aircraft performance by reducing aerodynamic drag and improving fuel efficiency. This piece delves into the science behind winglets, their role in aviation, and the various types of winglets used in modern aircraft.

The Physics of Flight and Winglets

Before focusing on winglets, we must first grasp the physics of flight, particularly the concepts of drag and vortices.

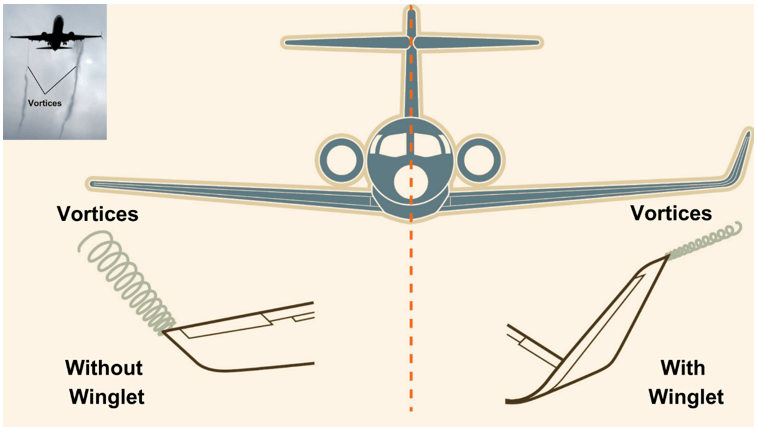

The elemental physics of flight revolves around the principle of lift, generated by the air pressure difference on the above and below surfaces of an aircraft’s wings. The pressure is low on the top surface of the wing and high on the bottom, causing air to flow around the wingtip from the bottom to the top. This flow results in swirling air masses known as wingtip vortices. These vortices create a form of aerodynamic drag known as induced drag. It is most significant at high angles of attack, such as during takeoff and landing, and at high altitudes where air is thin. It slows down the aircraft, causing additional fuel burn and making the flight less efficient.

To combat this, engineers have developed a solution known as winglets. These vertical or near-vertical extensions at the wingtips act as a barrier that reduces the intensity of these vortices and henceforth reduces induced drag. By doing so, winglets enhance the aircraft’s overall aerodynamic efficiency, which leads to increased range and reduced fuel consumption.

Pre-Winglet Solutions to Reduce Induced Drag

Engineers and designers explored various methods to reduce induced drag before the advent of winglets. A slightly different tactic was the induced drag reduction by increasing the aspect ratio of the aircraft wing. The aspect ratio is a term that defines the ratio of the wing’s length to its width. Wings with a high aspect ratio (long and narrow) are better at minimizing the induced drag than wings with a low aspect ratio (short and broad). It is because longer wings have less noticeable wingtip vortices.

The Role of Winglets: Countering Drag and Vortices

The discovery of winglets happened as a solution to mitigate the effects of drag and vortices. They act as a barrier between the high-pressure and low-pressure air flows, reducing their ability to form vortices by extending vertically or near-vertically at the wingtips.

They also generate a small amount of forward lift, which helps counteract the backward component of the lift induced by the vortices. This results in less drag, improved fuel efficiency, and extended cruising range, translating into significant cost savings for airlines.

A slightly different tactic to reduce the induced drag is by increasing the aspect ratio of the aircraft wing. The aspect ratio is a term that defines the ratio of the wing’s length to its width. Wings with a high aspect ratio (long and narrow) are better at minimizing the induced drag than wings with a low aspect ratio (short and wide). This is because longer wings have less noticeable wingtip vortices.

Types of Winglets: A Look at Different Designs

Multiple types of winglets are used in commercial aviation today. Each has its unique design and benefits. Below are some examples of the most frequently encountered ones

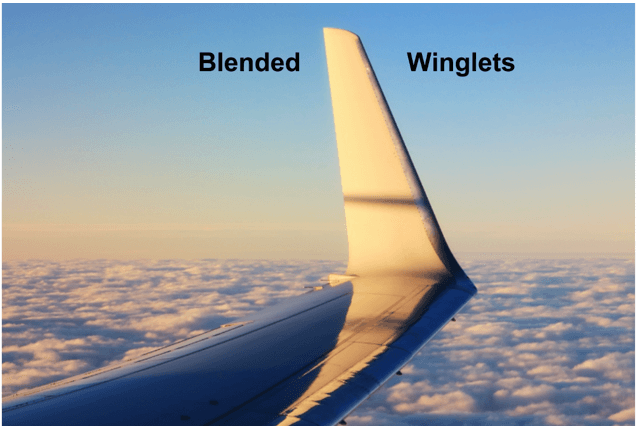

Blended Winglets

The most familiar category of winglets noticed in commercial aviation today is the blended winglet. First developed by Gulfstream in the 1990s, these winglets gently curve outwards and blend smoothly into the wing, hence their name. They are proven to reduce drag, increase fuel efficiency, cut down on emissions, and even reduce noise output. Commercial aircraft such as Boeing 737s, 757s, and 767s commonly utilize blended winglets.

Sharklets

Sharklets, the Airbus answer to the blended winglet. Despite the edgy name, the design is quite similar to that of blended winglets. The Airbus A350 features a notably altered sharklet with a unique curved design that minimizes aerodynamic stress. They have introduced Sharklets with its newer A320 family models and all A320neo family aircraft. Widebodies like the Airbus A350 also utilize a slightly modified sharklet design for enhanced efficiency.

Split Scimitar Winglets

Split-scimitar winglets are an enhancement of the blended winglet design. They feature two distinct pieces, with the lower part angled downwards, providing even more drag reduction. These winglets are commonly found on Boeing 737 MAX aircraft.

Raked Wingtips

Raked wingtips, inspired by the wings of gliders and birds, are a unique design caught on particular Boeing aircraft like the 787 Dreamliner, 767-400, 777, and 777X. These wingtips extend around 5 meters from the wing’s end to create more surface area, reducing drag and enhancing fuel efficiency. They are usually seen as a ‘flattened down’ version of winglets.

Canted Winglets

Canted winglets are short and feature a distinctive upward slope. Boeing 747-400 was the first to introduce them. They can be found on older Airbus widebodies such as the A330 and A340. Due to the retirement of many aircraft that deploy them, they have become a rarer sight recently.

Spiroid Winglets

The spiroid winglet concept aims to maximize the advantages of blended winglets by effectively incorporating them into the wing structure. These winglets resemble elongated wingtips bent upwards in a complete loop, forming an extensive and sturdier structure. The initial iteration of spiroid winglets, which were utilized on the Gulfstream II aircraft in the 1990s, had a more circular shape when compared to the current version. Through flight testing, refinements were made to the design, resulting in a more arched shape. In addition, the inboard part of the spiroid winglet was shifted farther aft and outboard to be closer to the wingtip vortex

Comparing Different Types of Winglets in Terms of Efficiency and Performance

When comparing different types of winglets, it is essential to consider their specific design features and intended applications. While all categories of winglets offer drag reduction and improved efficiency, the extent of these benefits can vary.

Blended winglets, with their smooth transition from the wing to the winglet, provide a balance between aerodynamic performance and aesthetic appeal. Raked wingtips, on the other hand, offer a larger span and more significant lift improvement, making them ideal for long-range aircraft. Sharklets, with their upward curve, excel in reducing drag and maximizing fuel efficiency.

Eventually, the design of the winglet depends on the airplane’s specific needs and performance characteristics.

Challenges and Considerations when Implementing Winglets

While winglets offer numerous benefits, their implementation is not without challenges and considerations. One of the main challenges is the structural modification required to integrate winglets into existing aircraft designs. This process involves extensive engineering analysis and certification, which can be time-consuming and costly.

Additionally, the effectiveness of winglets can vary depending on the specific aircraft and operating conditions. Factors such as wing design, wing loading, and flight profile can influence the performance of winglets. Therefore, thorough testing and analysis are necessary to ensure optimal results.

The Future of Winglets: Towards More Efficient Flights

As the aviation industry continues to aim for greater efficiency, the design of winglets is likely to evolve even further. Modern aircraft are highly equipped with advanced winglets to enhance performance and contribute to significant fuel savings. As the quest for efficiency continues, one thing is sure – winglets will continue to be an integral part of future aircraft design.

To sum up, winglets are a vital part of advancement in airframe structure. Not only do they enhance the aerodynamic performance of aircraft, but they also help to improve fuel efficiency and reduce costs. Understanding the principles of flight and how winglets work allows us to appreciate the notable engineering behind these simple yet groundbreaking devices. Each style of winglet, whether blended, split scimitar, sharklets, raking, or canted, serves a specific purpose and contributes to the wonder of modern aviation.